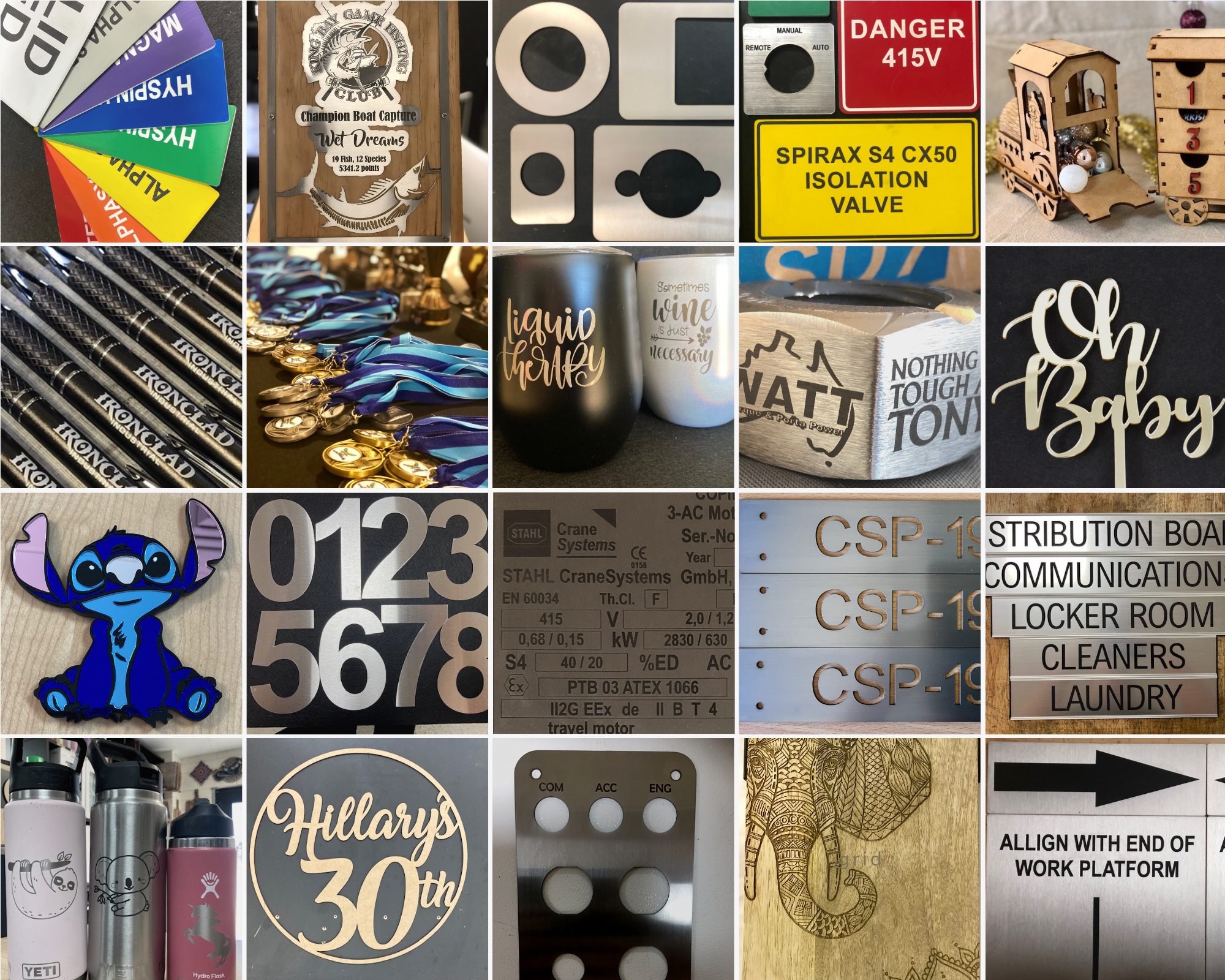

CORE COMPETENCIES

Our experienced team will provide a variety of laser cutting, etching, marking, and engraving processes that are supported by the latest design software, premium materials, and state-of-the-art equipment to manufacture to your exact requirements.

We understand that quality is of utmost importance, so we strive to deliver exceptional results on every project. Please don’t hesitate to reach out if you have any questions or need more information – we are here to help!

LASER CUTTING

Laser cutting works by directing a highly concentrated laser beam onto the product, resulting in a precisely cut edge with a high-quality surface finish and an accurate reproduction of your design or product requirements.

Utilising all of our machines we can manufacture from, ranging from a thickness of 1 thou to 15mm

- Stainless Steel

- Aluminum

- Carbon (Mild) Steel

- Galvonised Alloy

- Acrylic

Each of the 6 machines has its own capabilities and specialties that make them critical for certain parts of the production process

LASER ENGRAVING

Laser engraving is a process where the laser beam physically removes the surface of the material to create a cavity that reveals an image at eye level.

During the engraving process the aligned laser fires, creating extremely high temperature. This causes the material to essentially vaporize, resulting in a cavity in the surface being created. Deeper marks with the laser engraver can be achieved by repeating with several passes.

There are many benefits when comparing laser engraving to traditional engraving.

Laser engraving can:

- Be used on several materials.

- Is more legible than traditional engraving for small objects such as jewellery.

- Provide you with endless font options.

- Lessen the chance of product damage or deformation.

- Be carried out much faster than traditional methods.

LASER MARKING

Laser marking is what happens when the beam interacts with the surface of a material, slightly altering its properties or appearance.

Laser marking is achieved by moving a low-powered beam slowly across the material using a method called discolouration, which creates high-contrast marks without disrupting the material.

The Laser heats the material, causing oxidation under the surface and turning the material black while it applies low temperatures to metal to anneal the surface without any contact to the product leaving the surface intact.

Laser marking requires a Fibre Laser and is the only way to permanently mark reflective metals, and Commercial Engraving & Cutting has one of the highest precision machines available.

MATERIALS

Our equipment and machines can cut, etch and mark a range of metals, acrylics and wood, including but not limited too;

- Stainless Steel

- Anodised Aluminium

- Steel

- Galvanised Steel

- Traffolyte ™, dual coloured industrial signage acrylic

- Acrylic/Perspex

- Glass

- Hard and softwoods

- Hard and softwoods

- Exotic and high-temperature alloys

- Copper

- Brass

- Nickel

- Gold

- Leather

If you need help deciding which material is best for your project, please don’t hesitate to reach out to us and our experienced team will be happy to provide guidance.

Address

1491 Lambert Rd, Karratha Industrial Estate WA 6714, Australia

Phone

0408 088 805

info@cecengraving.com.au

facebook.com/cecengrave